في إنتاج الجرعات الصلبة، أ آلة تعبئة الكرتون تُعدّ هذه المرحلة حلقة الوصل بين التغليف الأولي ووحدات الشحن النهائية. فهي تأخذ العبوات البلاستيكية الشفافة، والزجاجات، والأكياس، أو المجموعات الصغيرة، وتجمعها مع النشرات، وتحولها إلى كراتين جاهزة للبيع بالتجزئة أو للمستشفيات لتعبئة الصناديق ووضعها على المنصات.

بالنسبة لشركات الأدوية والمكملات الغذائية، يؤثر اختيار هذه المعدات بشكل مباشر على الامتثال لمعايير التصنيع الجيد، والترقيم التسلسلي، وإمكانية التتبع، والتسليم في الموعد المحدد، وكفاءة المعدات الإجمالية لقاعة التعبئة والتغليف. يشرح هذا الدليل وظيفة هذه المعدات في تعبئة الأدوية، والأنواع الرئيسية المتاحة، وكيفية عملها، والأهم من ذلك، كيفية اختيار الحل الأمثل لخطوط التعبئة والتغليف الخاصة بكم.

ج التنقيب عن الأحجار الكريمة م تقوم الآلة بتشكيل الكرتون المسطح إلى كرتون مفتوح، وتحميل المنتجات الصيدلانية والنشرات، وإغلاق الكرتون وختمه، وإخراج العبوات الجاهزة. وعادةً ما توضع بين معدات التعبئة والتغليف الأولية ومعدات نهاية خط الإنتاج. .

في بيئة منظمة، يجب على آلة تعبئة الكرتون أن تفعل أكثر بكثير من مجرد "وضع شيء ما في صندوق":

● تشكيل ونقل الكرتون

● تحميل دقيق لـ بثور زجاجات، أكياس أو مجموعات

● طي النشرة / دليل الاستخدام وإدخالها

● إغلاق الكرتون (بالطي أو اللصق) وميزات مقاومة العبث

●الترميز والتسلسل (الدفعة، تاريخ الانتهاء، رموز أحادية/ثنائية الأبعاد)

● فحص الوجود / الاكتمال والرفض التلقائي

تتضمن الوحدات الرئيسية عادةً ما يلي:

● وحدة تشكيل وتصنيع المجلات الكرتونية

● نظام تغذية المنتج

● قسم طي وتغذية المنشورات

● نظام نقل الكرتون (جيوب / عروات / سلاسل)

● وحدة الإغلاق والختم

● أجهزة الترميز والفحص والرفض

● وحدة التحكم المنطقية القابلة للبرمجة (PLC)، وواجهة الإنسان والآلة (HMI)، وأنظمة الحماية

فيديو تعريفي لآلة تغليف الكرتون

وحدات شبه أوتوماتيكية

● تتم عمليات التشكيل والإغلاق بشكل آلي، بينما يقوم المشغلون بتغذية المنتجات أو المواد الخام يدويًا.

● مناسب للدفعات السريرية، والأحجام المنخفضة، والتغييرات المتكررة في الشكل.

وحدات أوتوماتيكية بالكامل

● تتم عمليات التشكيل والتحميل وإدخال النشرة والإغلاق بشكل آلي.

● مناسب للإنتاج التجاري، والمستحضرات الغذائية ذات الحجم الكبير، وشركات التصنيع التعاقدي الكبيرة.

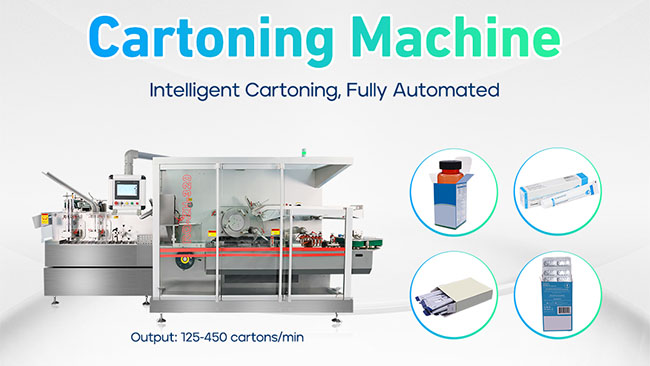

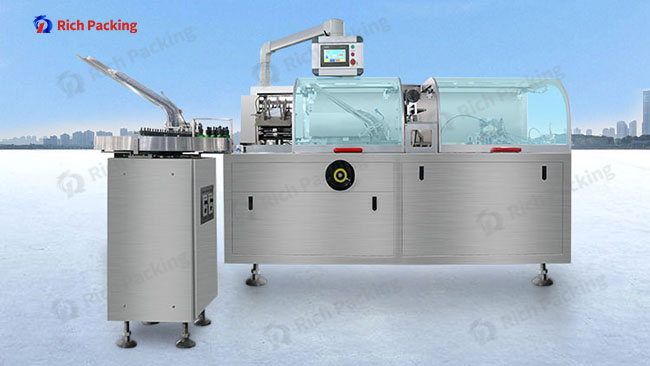

ومن الأمثلة العملية على الحلول الآلية بالكامل ما يلي: طراز أفقي RQ-ZH-130W من شركة ريتش باكينج. وهي تدمج الأنظمة الميكانيكية والكهربائية والبصرية لأتمتة تشكيل الكرتون وتحميل المنتجات والكشف عن النشرات وطباعة الرموز والإغلاق في دورة واحدة مستمرة.

آلة تعبئة الكرتون الأفقية

● يتم دفع المنتجات إلى داخل الكراتين من الجانب.

● الخيار القياسي في صناعة الأدوية للأشرطة والزجاجات والأنابيب والعبوات المركبة.

آلة تعبئة الكرتون العمودية

● يتم إسقاط المنتجات أو وضعها من الأعلى في الكراتين المفتوحة.

●أكثر شيوعًا في الأغذية ومنتجات العناية الشخصية؛ ويستخدم في صناعة الأدوية لأشكال معينة من الزجاجات أو البرطمانات.

حركة متقطعة

● يتم فهرسة الكراتين والتوقف لفترة وجيزة عند كل محطة.

● تصميم أبسط، تغييرات أسهل في التنسيق؛ مثالي للسرعات المتوسطة والعديد من وحدات التخزين.

حركة مستمرة

● تتحرك الكراتين باستمرار بينما تتم مزامنة العمليات مع التدفق المتحرك.

● مصمم للسرعات العالية جدًا والأحجام الكبيرة والمستقرة.

على الرغم من اختلاف التصاميم الميكانيكية، إلا أن التسلسل الأساسي متشابه:

1. تغذية وتشكيل الكرتون

2. نقل الكرتون في جيوب أو حقائب

3. طي وتركيب الوريقات

4. تحميل المنتج

5. إغلاق الكرتون وختمه

6. الترميز والتسلسل

7. التفتيش

8. الرفض والتسريح

لـ آلة تغليف الكرتون بالبثور خط:

●تخرج البثور من آلة تغليف الفقاعات ويتم ترتيبها على سير ناقل.

● يقوم نظام التغذية بتجميع العدد المطلوب من البثور.

● يتم فتح الكرتونات الفارغة، ويتم طي المنشورات ووضعها في مكانها.

● يقوم دافع أو روبوت بتحميل مجموعة البليستر والمنشور في الكرتون المفتوح.

● يتم إغلاق الأغطية وثنيها أو لصقها؛ ثم تتم طباعة الرموز والتحقق منها.

● يتم رفض العبوات المعيبة (التي تفتقر إلى الغلاف/المنشور، أو رمز خاطئ، أو تلف).

تتطلب الأشكال المختلفة تصميمات تغذية مختلفة:

● دافعات وسيور ناقلة دلوية للعبوات البلاستيكية والزجاجات والأنابيب

● روبوتات التقاط ووضع المنتجات الهشة أو غير المنتظمة

● أنظمة التحميل العلوي في التصاميم الرأسية

يمكن طي المنشورات مسبقًا أو طيها عبر الإنترنت؛ ويجب أن تمنع وحدة الطي والتغذية التغذية المزدوجة والانحشار وحالات فقدان المنشورات.

يقوم نظام التحكم المنطقي القابل للبرمجة (PLC) ونظام المؤازرة بتنسيق الحركة والوصفات والإنذارات. وتتولى الطابعات والكاميرات معالجة عمليات الدفعات/تاريخ انتهاء الصلاحية والتسلسل. وتتبادل الوحدة البيانات مع خوادم نظام إدارة التصنيع (MES) أو خوادم التسلسل، وتزامن آليات الرفض مع نتائج الفحص بحيث لا تغادر سوى العبوات المطابقة تمامًا. آلة تغليف الكرتون .

تطبيق آلة تعبئة الكرتون

استخدم هذه المعايير كقائمة مرجعية عند تقييم أي شيء آلة تعبئة الكرتون لخطوط تعبئة الأدوية.

ابدأ بمصفوفة واضحة من المنتجات والعبوات:

● أشكال المنتج – عبوات نفطة، زجاجات، أكياس، قوارير، محاقن، مجموعات مركبة

● أنماط التغليف – عبوة نفطة واحدة، عبوة نفطة متعددة، زجاجة + جهاز، مجموعات بداية

● تصميم الكرتون – كرتون قابل للطي بشكل مستقيم، أو قابل للطي بشكل عكسي، أو مغلق بالغراء، أو بقفل سريع، أو بنافذة، أو كرتون للعرض

الأسئلة الرئيسية:

●هل يمكن للمعدات أن تغطي أبعاد الكرتون ودرجات الورق المقوى بشكل موثوق؟

●هل نظام تغذية المنتج مناسب لتصميم عبوة البليستر، أو شكل الزجاجة، أو تكوين المجموعة؟

● ما مدى سهولة إضافة حجم كرتون جديد أو مكون إضافي لاحقًا؟

يجب دائمًا تقييم السرعة جنبًا إلى جنب مع فعالية المعدات الكلية (OEE) وعملية التغيير:

السرعة الاسمية مقابل السرعة الفعلية

● اطلب بيانات الإنتاج الحقيقية، وليس فقط الحد الأقصى لعدد الكراتين في الدقيقة.

● تحقق من عدد مرات حدوث التوقفات الصغيرة ومدى سرعة استعادة النظام.

المطابقة بين المنبع والمصب

● قم بمحاذاة سرعة الوحدة مع خطوط التعبئة في عبوات البليستر أو الزجاجات أو الأكياس.

● توفير مساحة احتياطية حتى لا تؤدي التوقفات القصيرة إلى عمليات إيقاف تشغيل متتالية.

التخطيط للنمو ودورة الحياة

● حدد نطاق سرعة يدعم الحجم الحالي والنمو على مدى 5-10 سنوات.

● تجنب تحديد السرعة بشكل مفرط إذا كانت وحدات التخزين كثيرة والدفعات صغيرة؛ فقد تعوض خسائر التغيير السرعة الاسمية العالية.

في بيئات شركات الأدوية والمكملات الغذائية متعددة المنتجات، غالباً ما تكون المرونة أكثر قيمة من السرعة المطلقة. ركز على:

عدد الصيغ

● ما عدد أحجام الكرتون، وتصميمات البليستر، وأحجام الزجاجات، وتنسيقات النشرات التي يجب دعمها؟

سير عمل التغيير

● ما هي الأجزاء التي يجب استبدالها؟

●هل قطع الغيار خفيفة الوزن ومحددة بوضوح؟

●هل التعديلات تتم بدون أدوات أم أنها تتطلب أدوات وإعادة ضبط؟

إمكانية التكرار والتوجيه

● هل تم تحديد المواقع بمقاييس ونقاط مرجعية؟

● هل يمكن للوحدة تخزين معلمات التنسيق كوصفات مع مواضع المؤازرة؟

الأوقات النموذجية

● اطلب فيديو التغيير والأوقات الموثقة لتغيير التنسيق "الكامل" و"الطفيف".

● قارن وقت التوقف السنوي الناتج عن عمليات التغيير عبر الأنظمة المرشحة.

ممارسات التصنيع الجيدة وقابلية التنظيف أمران لا يقبلان المساومة:

المواد والأسطح

● الفولاذ المقاوم للصدأ والألومنيوم المطلي في مناطق المنتج، والأسطح الملساء والزوايا المستديرة

● الحد الأدنى من مصائد الغبار وعدم وجود مواد مسامية غير ضرورية

سهولة الوصول والتنظيف

● ما مدى سرعة فتح الحواجز وتنظيف الأحزمة والموجهات والجيوب؟

●هل توجد تجاويف يصعب فحصها أو تنظيفها؟

إزالة العوائق من الخط

●هل من السهل التأكد من أن جميع الجيوب فارغة بين الدفعات؟

●هل توجد إجراءات واضحة وميزات تصميم تمنع التلوث المتبادل والخلط؟

قد تواجه آلة تعبئة الكرتون التي تبدو مثالية على الورق صعوبات في خط الإنتاج الحقيقي إذا لم يتم التخطيط لدمجها بشكل جيد:

● التخطيط – اتجاه الخط، والطول المتاح، وفروقات الارتفاع، وإمكانية وصول المشغل

● الواجهات الميكانيكية – نقاط النقل، وسيور التجميع، وتسليم المنتجات

● واجهات التحكم – التعشيق بين المنبع والمصب، ومنطق التشغيل/الإيقاف، وإيقاف الطوارئ، ومشاركة الإنذارات

تؤثر السلامة وسهولة الاستخدام بشكل كبير على الأداء على المدى الطويل:

● حماية كاملة بأبواب متشابكة وملصقات أمان واضحة

● واجهة مستخدم سهلة الاستخدام مع تنبيهات وصفحات تشخيصية بلغة بسيطة

● سهولة الوصول إلى مخازن الكرتون والنشرات، وقطع الغيار، ونوافذ الفحص

● رؤية جيدة لتدفق المنتج والكرتون

المعدات المصممة جيداً يسهل التدريب عليها وأقل عرضة للتوقفات المتعلقة بالمشغل.

عند مقارنة العروض، انظر إلى ما هو أبعد من سعر الشراء:

● قطع الغيار والمواد الاستهلاكية السنوية

● فترات الصيانة المخططة ووقت التوقف المتوقع

● تغيير أسعار قطع الغيار وأوقات التسليم

● تأثير السرعة، وكفاءة المعدات الإجمالية، وعملية تغيير خط الإنتاج على الإنتاج السنوي وتكلفة الكرتونة الواحدة

أسئلة متعلقة بالموردين:

● كم عدد المنشآت الصيدلانية التي يمتلكونها؟

●هل بإمكانهم توفير وثائق IQ/OQ ودعم PQ؟

●ما هي خدمات الدعم عن بعد، وشركاء الخدمة المحليين، ومراكز قطع الغيار المتاحة في منطقتك؟

في كثير من الأحيان، يؤدي الاستثمار الأولي الأعلى قليلاً مع الدعم القوي وفعالية المعدات الكلية الأفضل إلى أقل تكلفة إجمالية للملكية على مدار عمر الخط - وهذا هو السبب في أن العديد من المصانع تفضل الشراكة مع موردين متخصصين مثل Rich Packing، القادرين على توفير آلات تعبئة كرتونية متينة وملفات GMP كاملة ودعم خدمة طويل الأجل.

تطبيق آلة تعبئة الكرتون

تطبيق آلة تعبئة الكرتون

التصاميم الشائعة التي تتضمن هذا النوع من المعدات:

● تغليف بالبثور ← تعبئة الكرتون ← فحص الوزن / الترقيم التسلسلي ← تعبئة الصناديق ← رصّ البضائع على المنصات

● تعبئة الزجاجات ← وضع الملصقات ← تعبئة الكرتون ← تعبئة الصناديق

● أكياس صغيرة / عبوات لاصقة ← كرتون ← تغليف بالانكماش الحراري ← تعبئة في صناديق

توضيح نقاط التكامل مبكراً:

● ارتفاعات السيور الناقلة وسرعاتها وتسليم المنتجات

●التراكم المطلوب قبل الوحدة وبعدها

● إشارات التعشيق لبدء/إيقاف التشغيل وحالات الأعطال

● تتم مشاركة البيانات مع نظام التحكم في الخط، أو نظام SCADA، أو نظام MES

● المتطلبات: إنتاجية عالية جدًا، جودة ثابتة، قدرة عالية على التعامل مع الكرتون

● الخيار: نموذج حركة أفقية مستمرة أوتوماتيكي بالكامل

● التركيز: كفاءة المعدات الإجمالية العالية، وتكامل التسلسل القوي، والتشغيل السلس خلال فترات الذروة الموسمية

● الحاجة: تغييرات متكررة في المنتج والشكل، والعديد من الدفعات الصغيرة

● الخيار: نموذج أفقي متقطع مع تغيير سريع جدًا وبدون أدوات

● التركيز: المرونة، الحجم الصغير، سهولة إزالة العوائق وتنظيف الخطوط

● الاحتياجات: إنتاج متوسط السرعة، عبوات بيع بالتجزئة جذابة، إمكانية التوسع، والقدرة على معالجة أنواع مختلفة من المنتجات على خط إنتاج واحد

● خيار: منصة أفقية أوتوماتيكية بالكامل متوسطة السرعة يمكنها تشغيل عبوات البليستر والزجاجات والأكياس الأكبر حجمًا على نفس الآلة الأساسية

● التركيز: استثمار متوازن، مظهر الكرتون، خيارات الترقية المستقبلية (التسلسل، فحص إضافي)

● السعي وراء السرعة القصوى بدلاً من تحقيق استقرار في فعالية المعدات الكلية وأداء تغيير واقعي

● التقليل من شأن التعامل مع المنشورات، والذي غالباً ما يصبح السبب الرئيسي لتوقف العمل ورفضها

● تجاهل التنسيقات المستقبلية وتغييرات المنتج، مما يؤدي إلى عمليات تحديث مكلفة لاحقًا

● النظر فقط إلى سعر الشراء، وليس إلى التكلفة الإجمالية للملكية والدعم طويل الأجل

● إهمال الترقيم التسلسلي والاتجاهات التنظيمية عند تحديد مواصفات المعدات

● عدم إشراك الهندسة والإنتاج وضمان الجودة والتحقق عند كتابة مواصفات متطلبات المستخدم (URS)

س1. ما هي آلة التعبئة في تغليف الأدوية؟

إنه نظام يقوم بتشكيل الكراتين، وتحميل المنتجات الصيدلانية والنشرات، وإغلاق وختم العبوات، وتسليم الوحدات الجاهزة لتعبئة الصناديق وشحنها.

س2. متى يجب علي اختيار آلة تعبئة الكرتون الأفقية بدلاً من العمودية؟

في مجال صناعة الأدوية، تُعتبر التصاميم الأفقية هي المعيار القياسي للعبوات البلاستيكية الشفافة والزجاجات والعبوات المركبة. أما الوحدات الرأسية فتُستخدم بشكل أساسي للمنتجات سهلة التدفق أو لأشكال معينة من الزجاجات/المرطبانات.

س3. ما هو نطاق السرعة النموذجي لهذا النوع من المعدات في صناعة الأدوية؟

تتراوح سرعة الإنتاج من حوالي 60 إلى 80 كرتونة في الدقيقة على خطوط الإنتاج المرنة ذات التشكيلة المتنوعة، وتصل إلى أكثر من 300 إلى 400 كرتونة في الدقيقة على منتجات الصيدليات الكبيرة. يعتمد الاختيار الأمثل على معدات الإنتاج الأولية واحتياجات تغيير خط الإنتاج.

س4. كيف تدعم هذه الآلات التسلسل والتتبع؟

فهي تدمج الطابعات والكاميرات لتطبيق رموز التسلسل والتحقق منها، والاتصال ببرامج ذات مستوى أعلى، ورفض الطرود التي تحتوي على رموز مفقودة أو غير قابلة للقراءة تلقائيًا.

س5. هل يستطيع عامل تعبئة الكرتون الواحد التعامل مع أحجام متعددة من الكرتون والمنتجات؟

نعم، ضمن حدود معينة. يكمن المفتاح في عدد التنسيقات التي تحتاجها، ومدى تعقيدها، والمدة الزمنية اللازمة للتغيير بينها.

س6. ما هي المستندات المطلوبة عادةً لتأهيل معدات التعبئة والتغليف الجديدة بموجب ممارسات التصنيع الجيدة (GMP)؟

تشمل الوثائق النموذجية مواصفات متطلبات المستخدم (URS)، وبروتوكولات وتقارير DQ و IQ/OQ، ووثائق FAT/SAT، وإجراءات الصيانة، وعند الاقتضاء، وثائق التحقق من صحة نظام الكمبيوتر لأنظمة التحكم والتسلسل.

اختيار آلة تعبئة الكرتون ل إن خطوط تعبئة الأدوية قرار طويل الأمد، وليس مجرد مقارنة بين السرعة والسعر. الهدف الحقيقي هو تحقيق فعالية إجمالية مستقرة، والتزام سلس بمعايير التصنيع الجيد والتسلسل، وخط إنتاج قابل للتوسع مع نمو مجموعة منتجاتك.

إذا بدأتَ بمنتجاتك وتصاميم علبها الكرتونية، وحددتَ احتياجاتك الواقعية من حيث السرعة والحجم، ثم قيّمتَ مرونة التنسيق، ووقت تغيير المنتج، وتصميم التصنيع الجيد (GMP)، وسهولة التنظيف، وجاهزية الترقيم التسلسلي، وتكامل خط الإنتاج، ودعم الموردين بشكل عام، فسيتضح لك الخيار الأمثل. باستخدام هذه النقاط كقائمة مرجعية، يمكنك تجنب الآلات التي تبدو جيدة نظريًا ولكنها معقدة عمليًا، والتركيز بدلًا من ذلك على حلول مرنة وجاهزة للتصنيع الجيد (GMP) تدعم أعمالك بسلاسة بدلًا من أن تُصبح عائقًا أمام عملية التعبئة والتغليف.