في غائر الإنتاج، الاختيار الصحيح آلة عد العلكة يمكن أن تُحسّن كفاءة ودقة خط إنتاجك بشكل كبير. ستُفصّل هذه المقالة أهم فوائد آلات عد الصمغ لمساعدتك على اتخاذ قرار واعٍ أثناء عملية الشراء.

لماذا تختار آلة عد العلكة؟ الإجابة بسيطة: فهي تُؤتمت عملية العد الشاقة وتضمن نتائج دقيقة ومتسقة لكل دفعة. مقارنةً بالعد اليدوي أو الآلات التقليدية، تُقدم آلات عد العلكة العديد من المزايا الأساسية:

عدّ دقيق ومتسق، بغض النظر عن شكل العلكة. تضمن تقنية الاستشعار المتقدمة (مثل المستشعرات البصرية أو الليزرية) عدّ كل قطعة علكة بشكل صحيح.

من خلال أتمتة العملية، تُقلل آلة العد من مخاطر الأخطاء المرتبطة بالمعالجة اليدوية. تتولى الآلة عملية العد وتضمن احتواء كل عبوة على الكمية المحددة. غائر .

في الإنتاج الضخم، السرعة هي المفتاح. يمكن لآلات عد الصمغ معالجة كميات كبيرة من الصمغ بسرعة أكبر من العمل اليدوي، مما يساعدك على زيادة الإنتاج دون التضحية بالجودة والدقة.

من خلال خفض تكاليف العمالة وهدر المنتجات، يمكن لهذه الآلات توفير المال على المدى الطويل. فهي تعمل بشكل أسرع وأكثر دقة من العمل اليدوي، مما يجعلها استثمارًا قيّمًا على المدى الطويل.

تُعد كفاءة خط الإنتاج إحدى أهم مزايا آلة عد الصمغ. إليك بعض الطرق التي تُحسّن بها الكفاءة:

يمكن للعد الآلي تسريع الإنتاج دون زيادة أعباء العمل. حسب الطراز، آلات العد يمكن معالجة الآلاف من غائر في الدقيقة.

تم تصميم معظم آلات عد الصمغ الحديثة للعمل بشكل مستمر وتتطلب الحد الأدنى من الصيانة، مما يزيد من وقت الإنتاج ويقلل من وقت التوقف المكلف.

مع نمو أعمالك، يتسع نطاق عمليات آلة التحبيب لديك. سواءً كان مشروعًا صغيرًا أو خط إنتاج واسع النطاق، يمكن تكييف هذه الآلات لتلبية احتياجات مختلفة من خلال إعدادات مرنة تناسب حجم وكمية المواد. غائر .

الفرق الرئيسي بين آلة عد الحلوى وآلة العد العادية هو تصميمها ووظائفها المُحسّنة. فبينما تُستخدم آلات التكوير العادية عادةً للمواد الصلبة العادية غير اللاصقة صغيرة الحجم، صُممت آلات تكوير الحلوى للتعامل مع مواد أكثر تخصصًا مثل الحلوى الصمغية، وخاصةً للحلوى ذاتية الوزن واللزجة.

ستكون الحلوى لزجة ومتكتلة بسبب ارتفاع نسبة السكر فيها بعد الإنتاج والتخزين، وقد صُممت آلة عد الحلوى مزودة بفاصل أسطواني في القادوس لمعالجة هذه المشكلة. عند دخول الحلوى إلى القادوس، ستكون بعض الحلوى لزجة ومتكتلة، ويمكن تفتيتها وفصلها بواسطة فاصل الأسطوانات. كما أن سطح القادوس مصنوع من مادة تيفلون غير لاصقة للحلوى، مما يقلل بشكل كبير من مشكلة عدم إمكانية تفريغ الحلوى بسبب التصاقها في القادوس.

قطعة منزلقة هوائية

عند دخول الحلوى إلى قناة العد عبر القادوس، صُمم جهاز انزلاق هوائي في القناة الاهتزازية لفصل الحلوى التي قد تكون لزجة بشكل أكبر. يتحرك جهاز الانزلاق الهوائي ذهابًا وإيابًا من اليسار إلى اليمين، مما يُمكّن من فصل قطع الحلوى الصغيرة التي لا يمكن فصلها في فاصل الأسطوانة القادوسي، مما يضمن استقلالية الحلوى في قناة العد، وبالتالي دقة العد اللاحق.

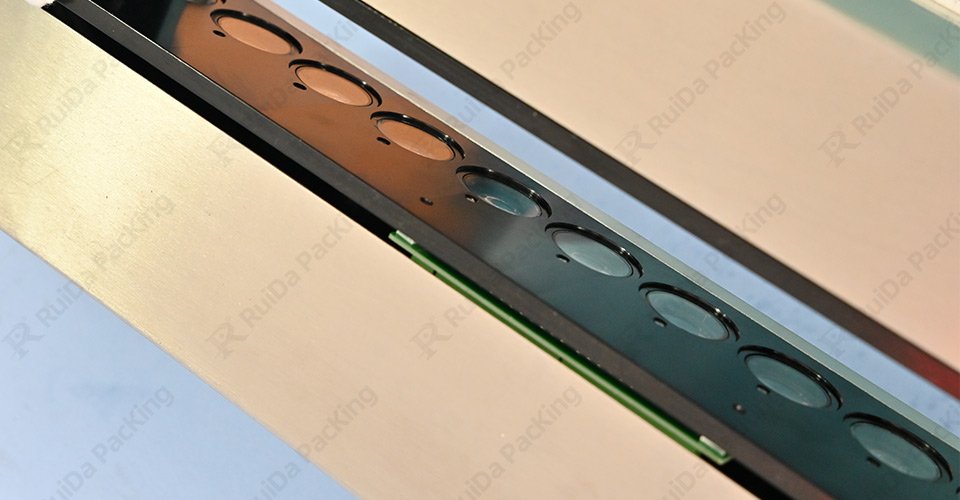

بكرات PTFE المضادة للتكتل

الأسطوانة المضادة للتكتل مصنوعة بالكامل من مادة PTFE، وهي مطابقة لمعايير سلامة الغذاء من حيث التلامس دون تلوث. سطح الأسطوانة مصمم بفتحات مقعرة ومحدبة متصلة، مصممة لتناسب أنواع وأحجام مختلفة من المنتجات. غائر ، كل ثقب يمكنه المرور عبر قطعة واحدة فقط من غائر ، وذلك لضمان عدم فصل القطع عن بعضها البعض غائر يمكن فصلها تمامًا بعد المرور عبر الأسطوانة، عندما يكون اثنان غائر تلتصق ببعضها البعض، حيث أن الضغط الناتج عن سطح الأسطوانة وقطر اللوحة المهتزة سوف يفصل بينهما غائر يلتصقان ببعضهما. وهذا يضمن استقلالية المادة الداخلة إلى حجرة الاهتزاز.

قناة اهتزاز من التفلون + غمازة

عندما يدخل الصمغ إلى قناة الاهتزاز، يتم معالجة سطح قناة الاهتزاز بمعالجة تفلون غير لاصقة من أجل التصاق الصمغ، ويتم تصميم السطح الأصلي لقناة الاهتزاز بمعالجة غمازة لتقليل مساحة التلامس بين الصمغ وقناة الاهتزاز لتقليل التصاق الصمغ بقناة الاهتزاز، مما يؤدي إلى عدم القدرة على الحركة.

منفذ تعبئة PTFE الموسع

صُمم منفذ عد العلكة بشكل ثماني الأضلاع مقلوب لزيادة حجمها وزيادة لزوجتها، مع فتحة تفريغ أكبر لتسهيل مرورها، بالإضافة إلى استخدام مادة PTFE الآمنة لتقليل لزوجة العلكة. صُمم غلاف التغذية السفلية ليناسب حجم فوهة العبوة التي تُعبأ فيها العلكة، بحيث يكون غلاف التغذية السفلية أكبر من فوهة الزجاجة، مما يسمح بوضع فوهة الزجاجة فيه عند عد الحبوب، كما أُضيفت إليه وظيفة الاهتزاز الهوائي، مما يحل مشكلة سقوط العلكة وتشويشها أثناء تعبئتها.

تأكد من دقة عد العلكة

الدقة عاملٌ أساسي في إنتاج العلكة. يتوقع العملاء عند شراء المنتج أن تكون الكمية المُشار إليها مطابقةً للكمية الفعلية. تتميز آلات عد العلكة بالدقة العالية، وتعتمد على عدد من التقنيات الرئيسية:

تستخدم هذه الأجهزة مستشعرات بصرية أو تقنية الأشعة تحت الحمراء لعدّ كل قطعة علكة. هذا يضمن دقة العد حتى مع العلكة غير المنتظمة أو اللزجة.

على عكس معدات العد التقليدية، تم تصميم آلات عد الصمغ للتعامل مع جميع أشكال الصمغ، سواء كان دائريًا أو مربعًا أو صمغًا مصممًا خصيصًا، حيث يمكن للآلة التعامل معها بدقة.

المتانة والاستقرار طويل الأمد من الاعتبارات الرئيسية عند اختيار معدات خط الإنتاج. يمكن لآلة عد الصمغ المُصنّعة جيدًا أن تدوم لسنوات مع الصيانة المناسبة، مما يضمن إنتاجًا سلسًا، ويقلل أيضًا من التكلفة الإجمالية للملكية.

غالبًا ما تُصنع عدادات الحبوب من مواد متينة تتحمل ساعات طويلة من العمل المكثف، مما يضمن عمرًا افتراضيًا طويلًا للمعدات. ويعني انخفاض الأعطال بقاء خطوط الإنتاج فعّالة.

صُممت العديد من آلات التكوير لتكون سهلة الصيانة، مما يُقلل من وقت وتكلفة تشغيل المعدات. مع الصيانة الدورية، ينخفض توقف خطوط الإنتاج بشكل كبير، ويُمكن تجنب الإصلاحات المكلفة.

قد تتساءل، ما هي مجالات استخدام آلة عدّ العلكة تحديدًا؟ مع أن اسمها يوحي بأنها تُستخدم أساسًا لإنتاج العلكة، إلا أن استخداماتها تتجاوز ذلك بكثير.

بالإضافة إلى غائر تعمل هذه الآلات بكفاءة مع منتجات طرية أخرى، مثل حلوى الجيلي والفيتامينات والمكملات الغذائية. هذه المرونة تجعلها قطعة أساسية في أي خط إنتاج يتطلب عدًّا وتعبئة دقيقة.

سواء كنت تعمل في صناعة الأغذية أو الأدوية أو المُغذيات، يُمكنك تعديل آلات عد العلكة لتلبية احتياجاتك. سواءً كنت شركة صغيرة أو شركة كبيرة، يُمكن استخدامها في بيئات إنتاج مُتنوعة.

اعتبارات رئيسية عند شراء آلة عد العلكة

عند شراء آلة عد العلكة، هناك بعض العوامل الرئيسية التي يجب مراعاتها. لا يقتصر الأمر على وظائف الآلة فحسب، بل يشمل أيضًا قدرتها على تلبية احتياجاتك الإنتاجية.

هل تستطيع الآلة التعامل مع أحجام وأشكال مختلفة من العلكة؟ تأكد من أن الطراز الذي تختاره مرن بما يكفي لاستيعاب أي تغييرات في خط إنتاجك.

يُعدّ دعم ما بعد البيع الموثوق أمرًا بالغ الأهمية عند شراء أي آلة صناعية. تأكد من أن الشركة المصنعة تُقدّم خيارات خدمة وصيانة فعّالة لضمان تشغيل الآلة بأفضل أداء.

ما مدى سرعة مساعدتك في استرداد أموالك باستخدام هذه الآلة؟ ابحث عن نموذج يوازن بين التكاليف الأولية والعوائد طويلة الأجل، مع زيادة سرعة الإنتاج وخفض تكاليف العمالة.

لتصور مزايا آلة عد العلكة بشكل أفضل، إليك جدول يقارنها بطرق العد التقليدية.

|

ميزة |

آلة عد العلكة |

طرق العد التقليدية |

|

الأتمتة |

مؤتمتة بالكامل |

يدوي أو شبه آلي |

|

دقة العد |

عالي |

معتدلة إلى منخفضة |

|

سرعة الإنتاج |

سريع |

بطيئ |

|

مشاركة العمال |

الحد الأدنى |

عالي |

|

التنوع (الأشكال/الأحجام) |

عالي |

محدود |

|

متطلبات الصيانة |

قليل |

عالي |

|

فعالية التكلفة |

عالية (طويلة الأمد) |

منخفض (قصير الأجل) |

آلات عد الصمغ هي معدات أساسية لأي خط إنتاج يُقدّر السرعة والدقة والفعالية من حيث التكلفة. بدمجها في عملية الإنتاج، يمكنك تقليل الأخطاء بشكل كبير، وتحسين الإنتاجية، وزيادة الربحية، مما يجعلها خيارًا ذكيًا للأنظمة الحديثة. غائر إنتاج.